Kiss-cutting at the Top Industry Level

Raide Cut cut 5 μm in thickness film

At Raide Cut, we specialize in cutting complex internal shapes for aircraft engine components. Our advanced cutting techniques ensure precision and accuracy, essential for meeting the stringent requirements of the aerospace industry.

With Raide Cut, you can trust that your aircraft engine components will be crafted with the highest level of precision, enabling you to excel in the competitive aerospace market.

Raide Cut is famous also for a quality kiss-cutting technique where a cutting mold is used to cut a film coating of 5 μm in thickness. We count this as a major achievement.

Raide Cut Steel Die

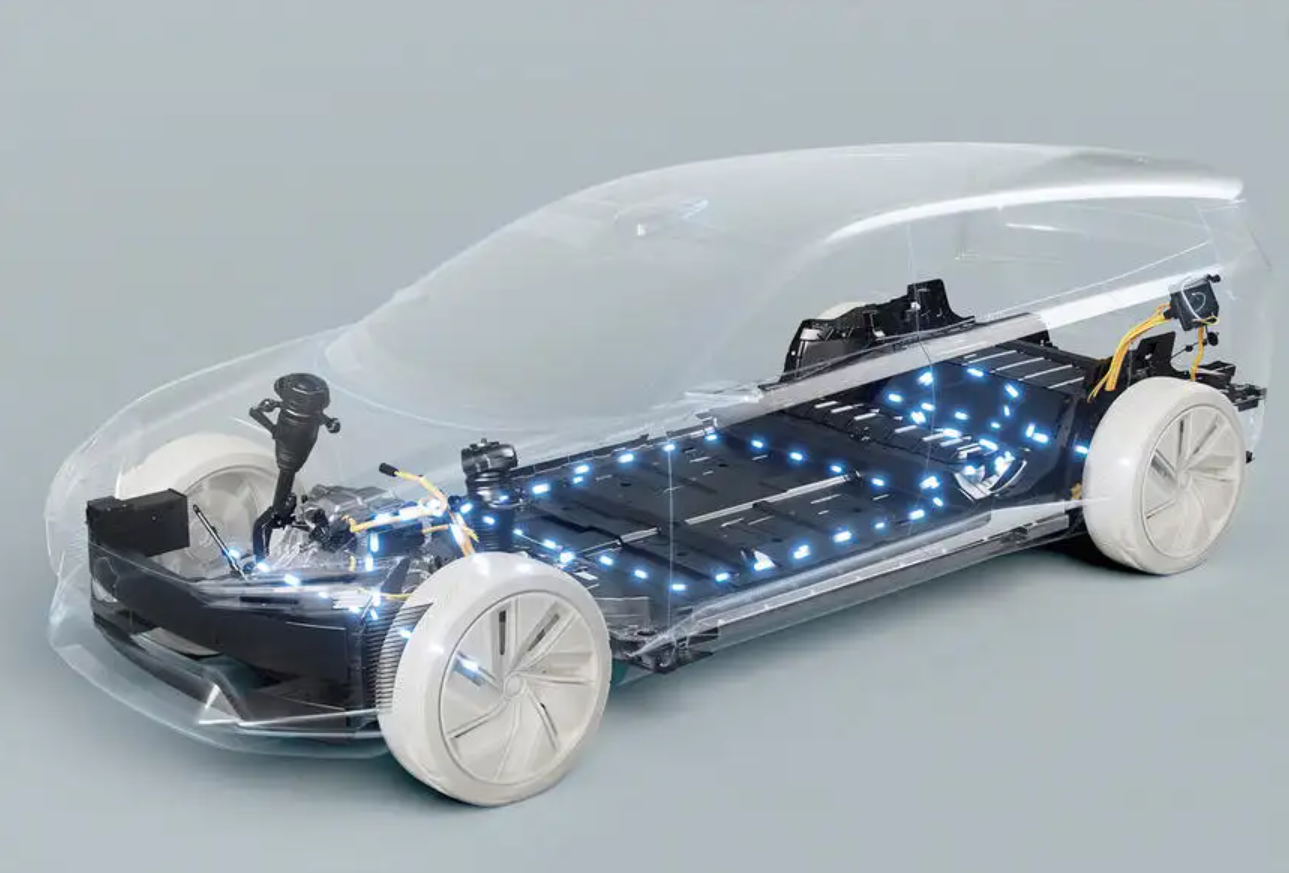

Raide Cut, is used across the EV Battery production line, where cutting die can endure over 5,500,000 shots.

Our precision cutting techniques are essential for creating high-quality battery components, which are crucial for performance and safety in today’s advanced battery technologies.

By utilizing our cutting-edge technology, we ensure that the components we produce meet the exacting standards required by leading battery manufacturers. This partnership allows us to contribute to the development of efficient and reliable battery solutions, essential for applications ranging from electric vehicles to consumer electronics.

We’ve worked with some of the best companies used Raide Cut

IT industry products requiring micro fabrication

Our diminutive punching mold die, 0.3 mm square

Raide Cut expertise has realized an extremely small punching mold, whose size is just 0.3 mm square.

Using ultra-fine processing and kiss-cutting progressive mold technique, this ultra-small mold enables cutting only coatings of 5 to 10 μm thickness on a 15 μm base film.

The “one-and-only” technique in Raide Cut

- Utilized in the variety of most-advanced manufacturing industries.

- Automotive, fuel cells, medical products and equipment, cosmetics and hair-care products.

- IT materials, and high-performance optical films.

Our Team

“Raide Cut is handcrafted by skilled artisans from Japan, boasting over 30 years of experience in the industry. Its precision is achieved through modern machinery and rigorous quality checks. This technique harmoniously combines traditional craftsmanship with advanced technology.”

Ito

Engineering Manager

YamaKita

Engineering Manager

Tatte

Project Manager

FAQs

What is steel rule die cutting?

Steel rule die cutting is a method used to cut, score, or crease materials using a die made from a steel rule. This process is commonly used for creating custom shapes and designs in various materials.

How does the steel rule die cutting process work?

In steel rule die cutting, a die made of a sharp steel blade is mounted on a flat surface. The material is placed beneath the die, and pressure is applied to cut through the material. The process can be done manually or with automated machines.

How do I determine the right die for my project?

Choosing the right die involves considering factors like the material thickness, desired shape, and production volume. Consulting with a die cutting expert can help you select the best option for your specific needs.

What is the typical lead time for steel rule die cutting projects?

Lead times can vary depending on the complexity of the die and the volume of the order. Generally, lead times range from a few days to a couple of weeks.